CHOPE-4YS AUTOMATIC-LOCK STITCH QUILTING MACHINE

Particulars / Design

| CHOPE-4YS TECHNICALPARAMETERS | ||||

| MODEL | 66” | 80” | 96" | 128” |

| POWER | 5.5KW | 5.5KW | 5.5KW | 6.5KW |

| MAIN SHAFT SPEED | 500-1000RPM | 500-1000RPM | 500-900RPM | 500-800RPM |

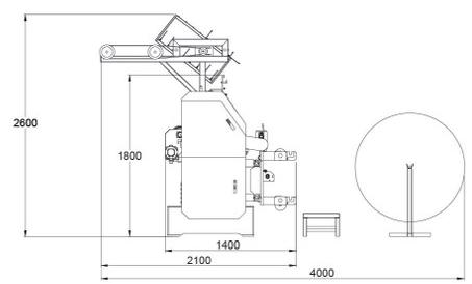

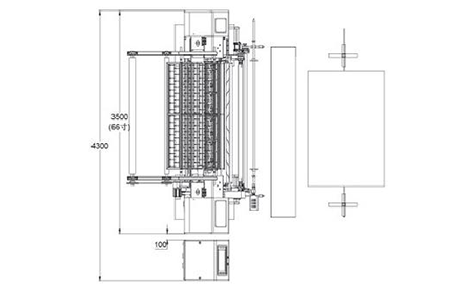

| DIMENSION(L×W×H) | 3900×4000×2600 | 4500×4000×2600 | 5000×4000×2600 | 5800×4000×2600 |

| PRODUCTION SPEED | 60-150M/H | 60-150M/H | 60-145M/H | 60-140M/H |

| QUILTING WIDTH | 1650MM | 2000MM | 2450MM | 3300MM |

| QUILTING THICKNESS | ≤30MM | ≤30MM | ≤30MM | ≤30MM |

| STITCH LENGTH | 3-8MM | 3-8MM | 3-8MM | 3-8MM |

| NEEDLE TYPE | 14#/21# | 14#/21# | 14#/21# | 14#/21# |

| SPACE BETWEEN NEEDLES | 25.4MM | 25.4MM | 25.4MM | 25.4MM |

| SPACE BETWEEN NEEDLE ROWS | 76.2+50.8+38.1+25.4 | |||

| MAX HORIZONALMOVEMENT | 204MM | 204MM | 305MM | 305MM |

| VOLTAGE | 380V/220V 60HZ/50HZ | |||

| GROSSWEIGHT | 2800KG | 3200KG | 3600KG | 4000KG |

Product Information

New shuttle guide rail support structure, using U-shaped bearing guide,shaft and bearing perfectly fit, making more durable and stable.

Advanced computer control system and mechanical manufacturingprocess reduce machine noise

The main shaft is controlled by frequency converter for automatically lifting the needle, and the saddle and roller are driven by servo

The needle bar adopts the needle bar frame structure without olling to avoid the occurrence of ollyfabrics, and the structure is firm and not easy to damage.Low maintenance costs